If you’re in the construction industry, you’re well aware of the importance of concrete testing. And when it comes to testing the compressive strength of concrete, a compression testing machine is an essential tool. But with so many options available in the market, choosing the right machine for your specific needs can be overwhelming. A compression testing machine is a significant investment, and you want to make sure you get the best value for your money. In this article, we’ll guide you through the process of selecting the right compression testing machine for your concrete testing needs. We’ll discuss the different types of machines, the factors to consider when making your selection, and some tips to help you make an informed decision. So, whether you’re a seasoned professional or just starting in the industry, this article is for you. Let’s get started!

Why is Compression Testing Important for Concrete?

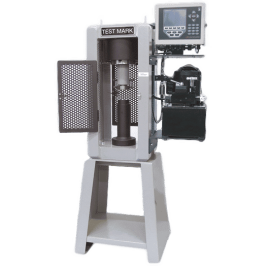

Before we dive into the factors to consider when choosing a compression testing machine, let’s first understand why compression testing is important for concrete. The compressive strength of concrete is one of the most critical properties that determine the quality and durability of concrete structures. It is the measure of the maximum amount of compressive load that concrete can withstand before it fails. The compressive strength of concrete is determined by testing concrete cylinders or cubes in a compression testing machine.

Compression testing is essential to ensure that the concrete used in construction meets the required strength specifications. It helps identify any deficiencies in the mix design, curing, or placement of concrete that could affect its strength and durability. Additionally, it is a necessary step in quality control and assurance for any construction project.

In summary, compression testing is crucial for assessing the strength and durability of concrete structures. Without compression testing, it would be impossible to ensure that the concrete used in construction meets the required strength specifications.

Factors to Consider When Choosing a Compression Testing Machine

Now that we’ve established the importance of compression testing, let’s discuss the factors to consider when choosing a compression testing machine. Here are some key considerations:

1. Accuracy

The accuracy of the compression testing machine is one of the most crucial factors to consider. It is essential to choose a machine that provides accurate and reliable results. An inaccurate machine can lead to incorrect conclusions about the strength of the concrete, which can have severe consequences for construction projects.

2. Load Capacity

The load capacity of the compression testing machine is another critical factor to consider. The load capacity is the maximum amount of force that the machine can apply to the concrete specimen. It is essential to choose a machine with a load capacity that is appropriate for the size and type of concrete specimens that you will be testing.

3. Load Frame Size

The load frame size is the size of the space where the concrete specimen is placed. It is essential to choose a machine with a load frame size that is appropriate for the size of the concrete specimens that you will be testing. A machine with a small load frame size may not be suitable for larger specimens, and vice versa.

4. Speed and Control

The speed and control of the compression testing machine are also critical factors to consider. The speed at which the machine applies force to the concrete specimen can affect the results. Additionally, the ability to control the speed and force during testing can help ensure accuracy and reliability.

5. Ease of Use

The ease of use of the compression testing machine is also an essential factor to consider. A machine that is complicated to operate can lead to errors in testing and increase the risk of accidents. It is essential to choose a machine that is easy to use and comes with clear instructions and training.

6. Price

Finally, the price of the compression testing machine is a crucial factor to consider. A compression testing machine is a significant investment, and you want to make sure you get the best value for your money. It is essential to choose a machine that meets your needs and fits within your budget.

Types of Compression Testing Machines – Manual vs. Automatic

Compression testing machines come in two main types: manual or automatic. Let’s take a closer look at each type:

Manual Compression Testing Machines

Manual compression testing machines are the most basic type of machine and require the operator to manually apply force to the concrete specimen. These machines are typically less expensive than other types but require more effort and time to operate. They are best suited for small-scale testing or when budgets are limited.

-

CM-0100 Series Compression MachinePrice range: $8693.00 through $10890.25

-

Extended Frame Compression Machines-500KPrice range: $25750.00 through $27820.00

-

CM-0030 Series Compression MachinePrice range: $4435.00 through $10125.00

-

High Capacity Series Compression Machines

-

CM-5000 Series Compression MachinePrice range: $22310.00 through $24140.00

-

CM-4000 Series Compression MachinePrice range: $15980.00 through $17230.00

-

Compression Machine 300KPrice range: $11980.00 through $13695.50

-

Compression Machine 250KPrice range: $9475.00 through $13820.00

Automatic Compression Testing Machines

Automatic compression testing machines use a motor to apply force to the concrete specimen and are fully automated. They are the most expensive type of machine but are also the easiest to use and provide the most accurate and reliable results. They are suitable for large-scale testing or when accuracy is essential.

-

Automatic Compression MachinesPrice range: $108.00 through $13495.00

-

Automatic Loading Controlled Compression Testing Machine

Understanding Load Capacity and Load Frame Size

Load capacity and load frame size are two critical factors to consider when choosing a compression testing machine. Let’s take a closer look at each factor:

1. Load Capacity

The load capacity of the compression testing machine is the maximum amount of force that the machine can apply to the concrete specimen. It is essential to choose a machine with a load capacity that is appropriate for the size and type of concrete specimens that you will be testing. A machine with a low load capacity may not be able to provide accurate results for larger specimens, while a machine with a high load capacity may be unnecessary and costly for smaller specimens.

2. Load Frame Size

The load frame size is the size of the space where the concrete specimen is placed. It is essential to choose a machine with a load frame size that is appropriate for the size of the concrete specimens that you will be testing. A machine with a small load frame size may not be suitable for larger specimens, while a machine with a large load frame size may be unnecessary and costly for smaller specimens.

In summary, it is essential to choose a compression testing machine with a load capacity and load frame size that is appropriate for the size and type of concrete specimens that you will be testing.

Choosing the Right Accessories and Software for Your Compression Testing Machine

Choosing the right accessories and software for your compression testing machine can help improve its accuracy and efficiency. Here are some key accessories and software to consider:

1. Grips and Fixtures

Grips and fixtures are attachments that hold the concrete specimen in place during testing. It is essential to choose grips and fixtures that are appropriate for the size and type of specimens that you will be testing.

-

Flexural Beam Test Device$1500.00

-

Cube Compression Jig Assembly$685.00

-

Compression Machine Spacers (CM-4000 & CM-5000)Price range: $61.00 through $319.00

-

Compression Machine Spacers (CM-3000)Price range: $61.00 through $201.00

-

Mounting StandsPrice range: $330.00 through $393.00

-

Hydraulic Parts and Limit Switch AssembliesPrice range: $277.00 through $4860.00

-

Perpendicular Verification DevicePrice range: $1.15 through $45.88

-

Compression Machine Spacers (CM-0030 & CM-2500)Price range: $61.00 through $245.50

-

Cylinder Splitting SetPrice range: $672.00 through $1108.00

-

Masonry PlatensPrice range: $3532.00 through $4125.00

-

Flexural Beam AttachmentPrice range: $2512.00 through $2535.00

-

Cylinder Loading Shelf$74.50

-

Stationary Carrier BracketPrice range: $877.00 through $1505.00

-

Draw Rod$635.00

-

6 Inch Cube Platen Test SetPrice range: $785.00 through $1598.00

-

2″ Cube Platen Test SetPrice range: $686.00 through $712.00

-

Cylinder Platen AssemblyPrice range: $574.00 through $595.00

2. Digital Readout

A digital readout displays the force applied to the concrete specimen during testing. It can help improve the accuracy of the machine by providing real-time feedback.

Shop Digital Readouts

-

TS17 Digital Indicator$2715.00

-

iD Digital Indicator$2085.00

-

i720 Digital Indicator$1758.00

3. Software

Software can help automate the testing process and provide more accurate and reliable results. It can also help with data analysis and reporting.

In summary, choosing the right accessories and software for your compression testing machine can help improve its accuracy and efficiency.

Maintenance and Calibration of Compression Testing Machines

Proper maintenance and calibration of your compression testing machine is essential to ensure its accuracy and reliability. Here are some tips for maintaining and calibrating your machine:

1. Regular Cleaning

Regular cleaning of the machine can help prevent dust and dirt from affecting its accuracy.

2. Lubrication

Lubricating the moving parts of the machine can help ensure its smooth operation.

3. Calibration

Calibrating the machine regularly can help ensure its accuracy and reliability. It is essential to follow the manufacturer’s instructions for calibration.

In summary, proper maintenance and calibration of your compression testing machine are crucial for its accuracy and reliability.

Conclusion

Choosing the right compression testing machine for your concrete testing needs can be overwhelming, but it is essential to ensure the accuracy and reliability of your results. By considering factors such as accuracy, load capacity, load frame size, speed, ease of use, and price, you can make an informed decision. Additionally, choosing the right accessories and software and maintaining and calibrating your machine can help improve its accuracy and efficiency. With the right compression testing machine, you can ensure the quality and durability of your concrete structures.