Showing 1–12 of 25 results

-

Binder Testing

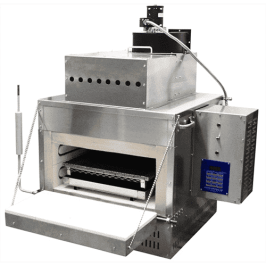

NCAT Furnace with Ignition™ Panel Upgrade

$16,099.00 – $17,431.00 Select options This product has multiple variants. The options may be chosen on the product page -

Binder Testing

ATS Bending Beam Rheometer

$116.00 – $48,541.00 Select options This product has multiple variants. The options may be chosen on the product page -

Binder Testing

NCAT Replacement Parts

$9.99 – $715.49 Select options This product has multiple variants. The options may be chosen on the product page -

Binder Testing

NCAT Accessories

$2.98 – $1,332.00 Select options This product has multiple variants. The options may be chosen on the product page -

Binder Testing

Replacement Parts for Binder Ignition Oven

$38.00 – $1,055.00 Select options This product has multiple variants. The options may be chosen on the product page -

Binder Testing

Draindown Basket

$155.00 – $160.00 Select options This product has multiple variants. The options may be chosen on the product page -

Binder Testing

Viscotester

$93.75 – $2,399.99 Select options This product has multiple variants. The options may be chosen on the product page