Your cart is currently empty!

Marshall Equipment

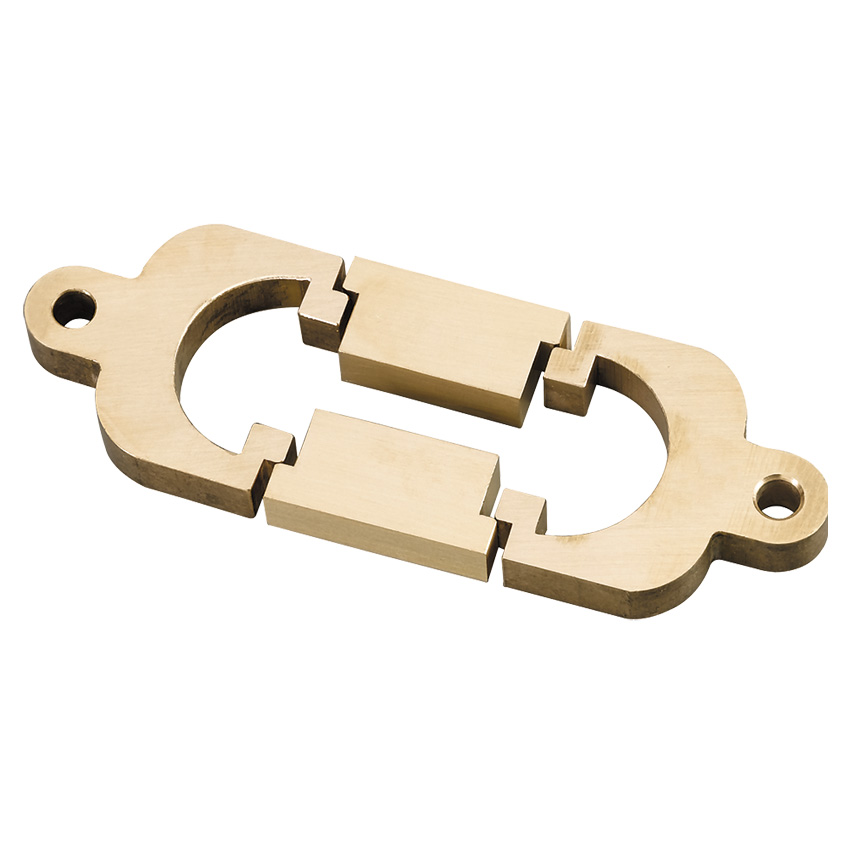

Marshall equipment measures the load and flow rate of asphalt specimens. Beginning with compaction into molds using manual or automated Marshall compactors, and conditioned in a water bath at the specified temperature. Marshall accessories include paper discs, the flowmeter kit, and mold extractors. As well as marshall breaking heads, and lottman breaking heads. The paper discs have a circular smooth edge with either 4″ or 6″ diameters. Placed in the bottom of compaction molds prior to filling with asphalt mixture to facilitate removal of the sample from the mold. The dial flowmeter measures flow during Marshall testing. The mold extractors work well with the compression tester for removing either 4″ or 6″ compaction mold specimens. Marshall breaking heads consist of an upper and lower cylindrical segment. They have 3″ inside radius of curvature for 6″ samples and 2″ for a 4″ sample. Lottman breaking heads test tensile strength in 4″ and 6″ samples. The Marshall compression machines measure resistance to plastic flow of bituminous paving mixtures. The machines have a motor with a reversing switch that produces uniform vertical 2″ movement per minute. The units include a calibrated load ring and dial indicator for determining test load. The load capacity is 10,000lbs and maximum piston travel is 3-1/2″.

-

Marshall Breaking Head 6″

$580.00 -

Marshall Breaking Head 4″

$440.00 -

Lottman Breaking Head 6″

$465.00 -

Lottman Breaking Head 4″

$330.00 -

IDEAL-RT Rutting Jig

$895.00 -

Marshall Water Bath 8.3 Gallon

$1,999.00 – $2,270.00 -

17.3gal Marshall Water Bath, Gas Strut-Assisted (120V / 60Hz)

$2,750.00 -

Elastic Recovery Mold

$186.00 -

Replacement Parts for Humboldt Automatic Marshall Compactors

$0.60 – $550.00 -

Smart-Jig

$5,315.00 -

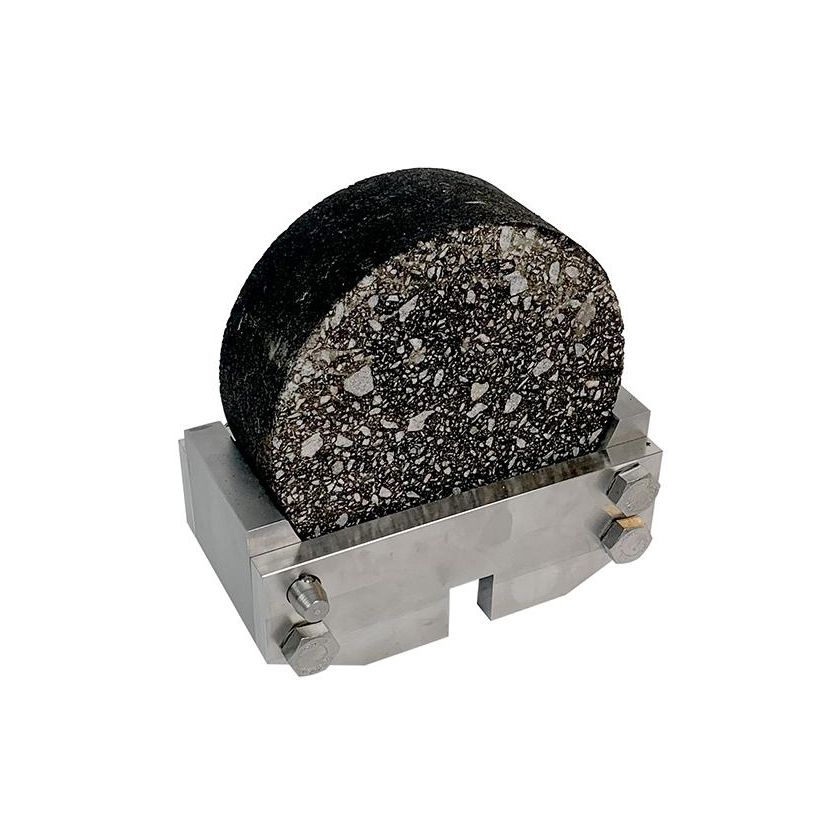

Semi-Circular Bend Test Fixture

$680.00 -

Sample Preparation Saw

$5,300.00 -

Economy Water Bath

$195.00 -

Water Bath (non-circulating)

$1,360.00 -

Large Deluxe Water Bath

$2,400.00